In the modern manufacturing landscape, “seeing” is no longer just a human capability. As Artificial Intelligence (AI) and Machine Learning (ML) converge with industrial operations, machine vision has become the “eyes” of the smart factory. From detecting microscopic defects on a high-speed assembly line to managing complex inventory with automated scanning, AI-driven vision is transforming production systems.

However, the transition from traditional rules-based vision to AI-driven systems places unprecedented demands on the network. At Cisco, we are bridging the gap between sophisticated AI analytics and the rugged reality of the plant floor.

Machine vision is no longer limited to simple “pass/fail” checks. By leveraging Cisco’s industrial and enterprise architectures, manufacturers are unlocking:

- Precision quality control: AI models can quickly identify anomalies in changing lighting or environmental conditions, reducing “false-fails” and minimizing waste.

- Inventory management & traceability: High-speed cameras can read barcodes and character-based data on moving assets with near-perfect accuracy, ensuring seamless logistics.

- Robotic coordination: Vision systems provide real-time location and orientation data, allowing robots to perform complex “pick and place” operations with surgical precision.

- Enhanced safety: Machine vision can detect unsafe human-machine interactions faster than traditional sensors, triggering immediate safety protocols to prevent accidents.

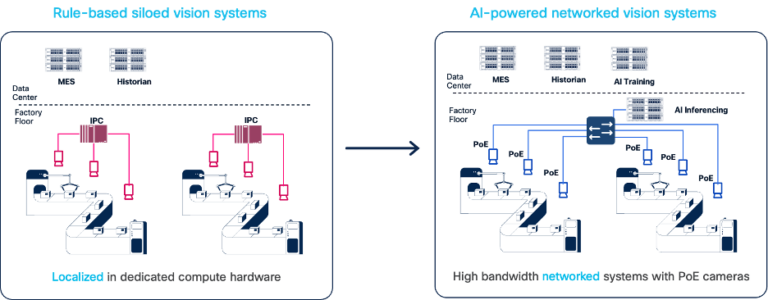

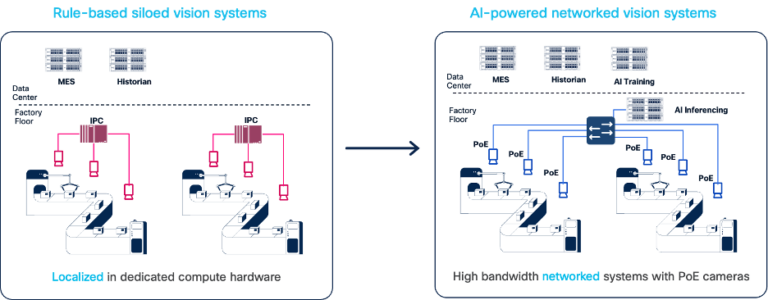

To deploy these use cases effectively, organizations typically choose from three primary architectural models, each supported by Cisco’s robust infrastructure:

- Embedded analytics: The AI processing happens inside the camera itself. This is ideal for low-latency, localized decisions where only metadata needs to be sent to the network.

- Direct connect: Cameras connect directly to a local Industrial PC (IPC). While this limits the number of cameras, it provides dedicated compute power close to the source.

- Networked vision server (the scalable choice): This is where the network truly shines. Multiple cameras stream raw data across standard Ethernet switches to a centralized GPU server or cloud environment. This model offers the highest flexibility and allows for the most powerful AI model training and historical data retention.

A machine vision system is only as good as the network that carries its data. To ensure these systems operate without a hitch, Cisco focuses on several critical network attributes:

- High bandwidth & multi-gigabit connectivity: Modern cameras produce massive amounts of data. Cisco’s IE3500 and Catalyst IE9300 Rugged Series switches provide 1Gb, 2.5Gb, and even 10Gbps uplinks to ensure that high-resolution image streams don’t become a bottleneck.

- Precise synchronization (PTP): In high-speed environments, timing is everything. Using the Precise Time Protocol (IEEE 1588), Cisco networks ensure all cameras fire at the exact same microsecond, enabling perfect 3D reconstruction and motion alignment without extra trigger wiring.

- Power-over-Ethernet (PoE): Why run three cables when you only need one? Cisco switches support high-wattage PoE (up to 90W), providing data, sufficient power to sustain GPU-integrated cameras, and synchronization over a single Ethernet cable, drastically reducing installation costs.

- Quality of service (QoS): Machine vision traffic can be bandwidth intensive.” Cisco’s advanced QoS policies prioritize critical PLC control traffic and PTP timing, ensuring that a heavy video stream never interferes with the safety or stability of the production line.

- Jumbo frame support: By supporting larger data packets (MTU ~9000 bytes), Cisco reduces the overhead on the network and the CPU, allowing for faster and more efficient image transfers.

- Security: The images captured by machine vision systems are often considered intellectual property; they may represent key manufacturing processes or products and are critical aspects of the manufacturing process. The devices and the data need cyber security protection. Cisco network infrastructure provides visibility and segmentation to protect these systems and the data they produce.

Integrating AI means connecting more devices, which can increase the attack surface. Cisco secures machine vision deployments using Cisco Cyber Vision for deep visibility into OT assets, Cisco TrustSec technology based micro-segmentation to prevent lateral movement of threats, and Secure Equipment Access (SEA) to allow vendors to tune vision models remotely without compromising the entire network.

The biggest challenge in industrial AI is the “fear of the unknown.” Will the high-bandwidth video crash the control system? How do I configure PTP for five different camera vendors?

Cisco removes this uncertainty through Cisco Validated Designs (CVDs). We don’t just sell hardware; we build entire vision ecosystems in our labs. We test specific cameras (from partners like Basler, Cognex, and Zebra) against our switches and software to create prescriptive, step-by-step implementation guides.

These CVDs are available to customers at no charge. They provide a blueprint for success, ensuring that your AI-driven machine vision project moves from “pilot” to “production” faster, with lower costs and significantly reduced risk.

AI-based machine vision is the future of industrial efficiency, but it requires a network that is more than just a “pipe.” It requires an architecture that is intelligent, resilient, and secure. With Cisco’s industrial networking leadership and our commitment to rigorous testing, you can see your way to a more productive future.

Explore the Machine Vision in Industrial Automation Environments Design and Implementation Guide, or schedule a 1:1 consultation with a Cisco manufacturing expert to learn more about you can harness this technology in your own factory.