Table of Contents

In this interview, industry experts Nimesh Khadka and Keith Freel explore how Raman-based PAT enhances hot melt extrusion by enabling real-time API monitoring, improving process control, and supporting Quality by Design in pharma.

Please could you give an overview of what hot melt extrusion is and why it has become so important in drug development?

Keith Freel: Hot melt extrusion (HME) is an advanced, but now established, technique for formulating drugs. It involves feeding an API with a polymer into a heated extruder, where the material is melted, mixed, and shaped.

Over 20 FDA-approved products use HME because it improves the solubility of poorly water-soluble drugs, stabilizes sensitive molecules, and enables controlled or sustained release. It’s also continuous, which is valuable for scalability and quality consistency. Beyond that, it supports innovative dosage forms such as filaments for 3D printing or thin films for oral delivery, making it highly versatile.

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

Why is real-time monitoring of APIs during hot melt extrusion important for pharmaceutical manufacturing?

Nimesh Khadka: Hot melt extrusion is widely used to improve drug solubility, bioavailability, and stability, but the process is highly dynamic. The state of the API—whether crystalline or amorphous—and its interaction with the polymer matrix directly affect drug efficacy and quality.

Traditional offline analysis is slow and can miss critical variations. Real-time monitoring with Process Analytical Technology (PAT), such as Raman spectroscopy, allows us to quantify APIs continuously, assess their physical state, and detect interactions as they happen. This not only improves process understanding but also enhances consistency, reduces batch-to-batch variation, and supports regulatory expectations for quality by design.

How does Process Analytical Technology (PAT), and Raman in particular, fit into the Quality by Design framework?

Keith Freel: PAT is integral to Quality by Design (QbD). QbD starts with defining a quality target product profile, identifying critical quality attributes (CQAs), and linking them to process parameters.

PAT tools like Raman spectroscopy enable us to monitor CQAs—such as API concentration, crystallinity, and dissolution—directly in real time. That helps ensure we remain within the defined design space and gives us immediate feedback to maintain control strategies. Raman, in particular, provides molecular-level information, which strengthens process understanding and supports regulatory compliance by embedding quality into the process rather than testing for it afterwards.

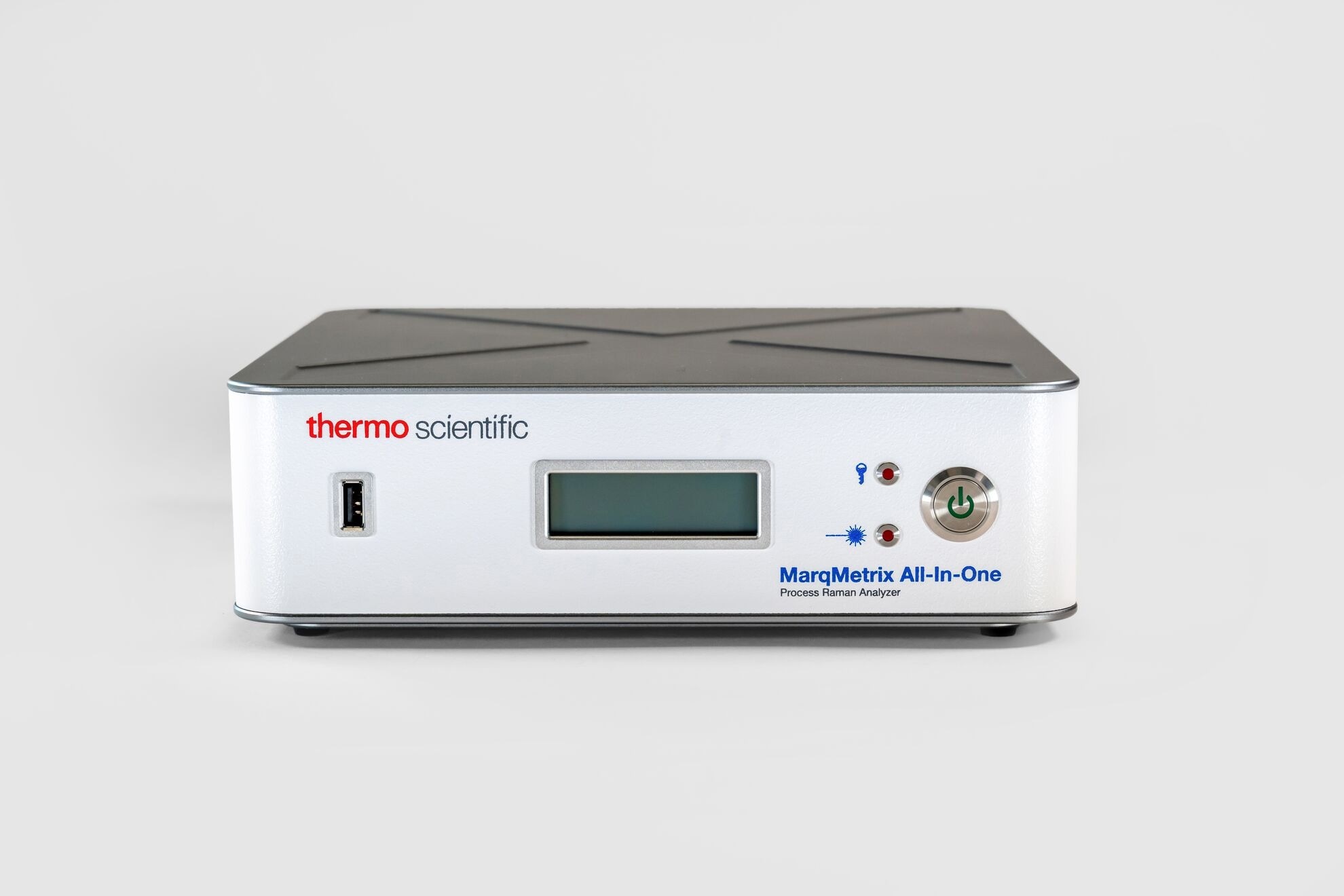

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

What was your experimental setup, and why did you choose acetaminophen as the model compound?

Keith Freel: We combined the Thermo Scientific Pharma-11 Twin Screw Extruder with the MarqMetrix Process Raman Analyzer, placing the Raman probe in the heated die. Acetaminophen was chosen because it’s a well-characterized API and a good model for studying solubility and polymorphism. We used Soluplus as the polymer and prepared blends of 0 %, 10 %, 25 %, and 50 % API. As the material moved through the extruder, Raman spectra were collected every 20 seconds. This setup allowed us to test whether Raman could reliably monitor concentration and physical state during a live HME process.

Image Credit: Thermo Fisher Scientific – Portable and Handheld Process Raman Spectroscopy

How effective was Raman in quantifying API concentration during extrusion?

Keith Freel: The Raman spectra showed clear changes corresponding to the acetaminophen concentration. Using partial least squares (PLS) regression with offline HPLC data for calibration, we built a predictive model that was highly accurate. The root mean squared error of calibration was around 0.5 %, and validation runs gave about 1.4 % error. This proved that Raman can provide reliable, real-time quantification. More importantly, it captured transient variations, for example, stabilization delays after concentration changes, that would not have been visible with only offline sampling.

Could Raman also detect polymorphic transitions or recrystallization of the API?

Keith Freel: Yes, Raman is sensitive to molecular form. We compared our spectra with published data for crystalline and amorphous acetaminophen and found that all extrudates remained amorphous throughout processing. No recrystallization was observed. This capability is critical because polymorphic transitions can alter drug performance. Raman can also be applied downstream, for example, to monitor cooling or stability studies, making it a valuable tool beyond just real-time process monitoring.

At what point did the MarqMetrix All-in-One Process Raman Analyzer prove most valuable in your study?

Nimesh Khadka: The analyzer’s flexibility and robustness made it especially valuable during in-line monitoring. Its compact size allowed easy integration into the extruder setup, and its stable calibration reduced the need for maintenance.

By operating in in-line mode, it provided continuous, real-time data. We were able to monitor acetaminophen concentration, confirm its amorphous form, and even detect subtle API–polymer interactions. These insights were critical for optimizing the process and ensuring product quality. The ability to use the same instrument in at-line or on-line configurations also adds to its versatility in both development and manufacturing environments.

What advantages does Raman offer compared to other PAT tools such as NIR or UV-Vis?

Nimesh Khadka: Each technique has strengths. UV-Vis is sensitive but less specific. NIR and Raman are both vibrational methods, but NIR is absorption-based while Raman is scattering-based, with different selection rules. They are complementary: some vibrations are stronger in NIR, others in Raman.

For example, Raman is excellent for non-polar bonds and is less sensitive to water, which is a big advantage in aqueous systems. NIR, on the other hand, may be more effective if fluorescence interferes with Raman. What makes Raman especially powerful is its ability to provide structural information, enabling us to study not just concentrations but also polymorphism and API–polymer interactions.

How scalable is this Raman-based PAT approach, and how do regulators view it?

Keith Freel: It’s scalable, though probe positioning must be carefully considered when moving to larger manufacturing systems. From a regulatory perspective, PAT is strongly encouraged. The FDA and ICH have both promoted PAT through quality by design initiatives. As long as Raman methods are properly validated and developed according to guidelines, they’re accepted as reliable tools for ensuring consistent product quality in both clinical and commercial manufacturing.

Finally, what opportunities are there for professionals to gain hands-on experience with Raman in HME?

Keith Freel: At the University of Maryland School of Pharmacy, we run the Tablets and Capsules short course, which includes lectures and practical labs. One of the sessions integrates Raman spectroscopy with hot melt extrusion using the Pharma-11 extruder. Participants learn how to collect real-time data, build models, and apply PAT principles in practice. It’s a unique opportunity to bridge theory with hands-on training, which is critical for anyone working in advanced pharmaceutical manufacturing.

About Nimesh Khadka

Dr. Nimesh Khadka is a Senior Product Application Specialist at Thermo Fisher Scientific and holds a PhD in Biochemistry from Utah State University. With extensive expertise in analytical biochemistry, spectroscopy and chemometrics, he is currently leading efforts to champion Raman spectroscopy as a process analytical technology (PAT). As an active member of the American Chemical Society, Nimesh remains at the forefront of emerging technologies and is committed to driving innovation to meet customer needs.

About Keith Freel

Dr. Keith Freel holds a Ph.D.in Physical Chemistry from Emory University and has extensive analytical chemistry expertise. As Research Project Director at the University of Maryland School of Pharmacy, he oversees advanced analytical projects supporting pharmaceutical and biomedical research. Previously, he spent over five years at Thermo Fisher Scientific as a Staff Scientist, where he led R&D efforts across a wide range of techniques including FTIR, Raman, NIR, XRF, ICP-MS, and multivariate statistical analysis.

About Thermo Fisher Scientific Inc.

Thermo Fisher Scientific is the world leader in serving science. The company enables its customers to make the world healthier, cleaner and safer by providing analytical instruments, equipment, reagents and consumables, software and services for research, analysis, discovery and diagnostics.

Thermo Scientific represents a broad range of high-end analytical instruments, chemistry and consumable supplies, laboratory equipment, software and services that enable integrated laboratory workflow solutions. Thermo Scientific is the new name for a trusted brand – Thermo Electron – that the world’s most renowned researchers, clinicians and scientists already count on to solve their analytical challenges. The brand is strengthened by the addition of equipment, consumables and reagents acquired from Fisher Scientific.

Fisher Scientific represents a family of global product and service brands comprising a complete portfolio of laboratory equipment, chemicals, supplies and services used in healthcare, scientific research, safety and education. Fisher Scientific brings these solutions to general research customers worldwide, and through Fisher HealthCare, Fisher Safety and Fisher Science Education it delivers the specialty equipment, supplies and services that customers want, when and how they want them. In addition to these two premier brands, Thermo Fisher Scientific also markets a range of specialty products, featuring well-known industry names such as Nalgene, Nunc and Remel. Offerings include consumables such as disposable laboratory glassware, plastic-ware and environmental sample containers ranging from vials, tubes and pipettes to microscope slides and syringes. These products are primarily sold through Fisher Scientific and our valued partners worldwide.