Lithium-ion batteries’ ability to deliver a lot of power from a small package have made them the go-to for makers and manufacturers alike. It’s not unusual now to find, say, microcontroller boards with integrated Li-ion chargers. Lithium-ion is so popular, in fact, that it’s easy to forget that other battery technologies exist, even when they’re a better fit.

These worthy alternatives include removable rechargeable nickel–metal hydride batteries. While NiMH cells can’t be recharged as many times as lithium-ion cells can and don’t offer the same power density, they’re cheaper and also safer. No need to ship them in boxes emblazoned with fire warning labels. The fact that NiMH cells deliver lower voltages than lithium has become less of an issue as the voltage demands of integrated circuits have fallen, with 3.3-volt and 1.8-V chips rapidly displacing the ubiquitous 5-V standard of yesteryear.

How to Make NiMH Easier to Manage

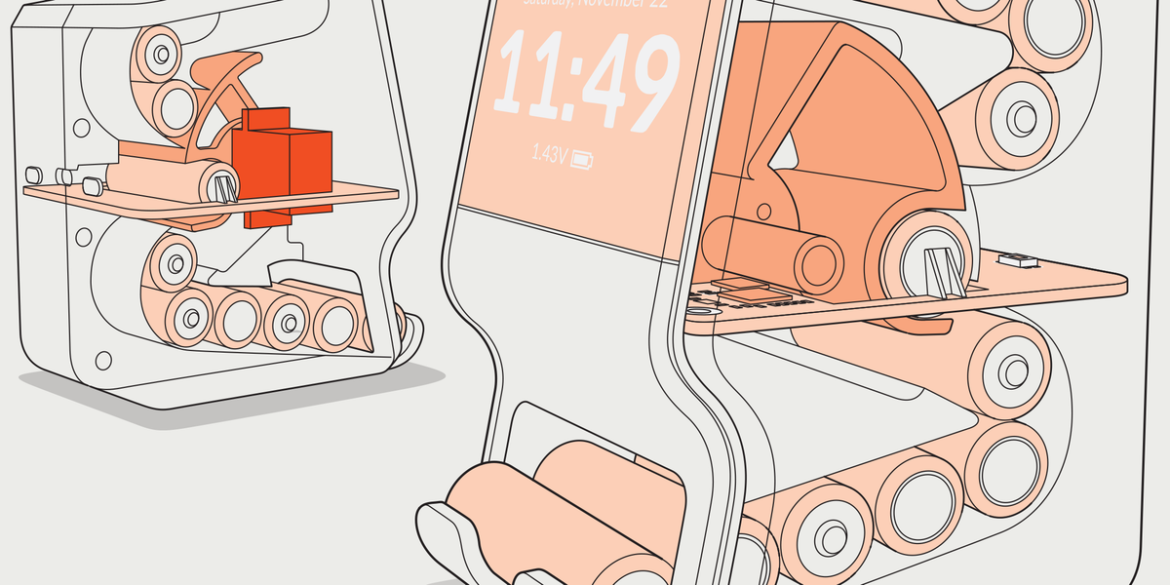

A handful of 3D-printed parts [bottom], a servo and screen [middle] and a single printed circuit board [top] are all that’s needed for the Spinc charger. James Provost

A handful of 3D-printed parts [bottom], a servo and screen [middle] and a single printed circuit board [top] are all that’s needed for the Spinc charger. James Provost

But it’s also true that recharging removable batteries can be a pain: You have to load them into a charger, which typically holds no more than four batteries at a time, and take care to put them in the right way. Otherwise you get no charging at best and irreversible damage to the cell and even overheating at worst.

To ease this pain point, I created the Spinc, a DIY device that charges up to seven NiMH AA batteries at a time and automatically figures out the polarity of each cell before charging it; when finished, it drops the batteries into a hopper. You can check on the charging status via a display that doubles as a clock.

In my day job, I work on industrial vehicles as an EE in a midsize German company. But I came to this project due to a personal interest in low-power electronics and after a fruitless attempt to harvest the last dregs of power from some nonrechargeable batteries. That failure—in a nutshell, my design needed a buffer battery that had to be recharged, which defeated the whole purpose of the project—got me thinking about rechargeable cells.

The hardest part of creating the Spinc was a self-imposed challenge. I wanted the charger to be compact and intuitive to use. This meant spending a lot of time perfecting the mechanism that takes a battery from the top of the charger, places and holds it between two electrodes while charging, and then drops the battery out the bottom before resetting and grabbing the next cell. A lot of careful iterations later, I had a set of seven 3D-printer files to create the parts that assemble to form the case and mechanism of the Spinc. To that, you just need to add the display, servo motor, and a printed circuit board with all the remaining components, plus an infrared proximity sensor that detects when a battery has been inserted and is ready to be placed between the charging electrodes.

To allow the battery to be charged regardless of which way it’s put into the charger, I used a classic H-bridge circuit, which is normally used to let DC motors run in either direction, with a few modifications that let it work at low voltages.

I decided to use a dedicated integrated circuit to manage the actual charging, with thermistors to watch out for overheating. While I could have used a microcontroller and written my own software to monitor the battery, NiMH cells have a very flat charging curve, and it’s easy to overshoot the charging cycle. Using an IC saved me from a lot of testing, and also gave me the ability to use a fast-charging mode.

However, it didn’t save me from some trial and error. The first charger IC I used was attractively compact at 2 by 2 millimeters. However, when I tried charging an AA battery, I discovered that the manufacturer assumed the end user would be charging two to four batteries at a time, all hooked up in series. Charging just a single battery meant the IC’s linear voltage regulator had to dissipate more heat than intended, and it quickly burned the chip out. I eventually found a somewhat larger (5.15 by 4.4 mm) charger IC that uses a switched-mode regulator and could handle the job. Finding that IC took a while, though, as the popularity of lithium batteries has reduced the availability of supporting components for NiMH.

The charging curve of NiMH follows a slow curve, with the battery’s voltage showing a dip of just 2 millivolts when fully charged, which is easily overshot and could lead to cell damage.James Provost

The charging curve of NiMH follows a slow curve, with the battery’s voltage showing a dip of just 2 millivolts when fully charged, which is easily overshot and could lead to cell damage.James Provost

The charger IC is connected to an RP2040 microcontroller, which reports the battery status on an LCD display. The RP2040 is also responsible for monitoring the proximity sensor and driving the servo that controls the internal feed mechanism, as well as responding to the Spinc’s push-button controls, which let you set the clock and start charging the batteries. The entire device is powered via a USB-C socket.

Most of the electronics are surface-mounted on a PCB that has a large center cutout to allow the batteries to pass through it. I designed the PCB in KiCad and had it fabricated by JLCPCB. To make it easier to fabricate the boards correctly, I didn’t try to specify 90-degree angles for the corners of the center cutout. Instead, I went with rounded corners, which are easier for the cutting tooling to follow.

The result is a desktop charger that’s as convenient to use as possible. A full set of PCB schematics, bill of materials, 3D printer files, and firmware files are available from the project page on GitHub. I hope it helps ensure that whenever you need a freshly charged NiMH battery, there’s one right at hand!

From Your Site Articles

Related Articles Around the Web